Precision Parts Machining in Kaukauna, WI

Introduction to Precision Parts

Precision machining is the foundation of 4M Machine LLC. For more than 20 years, we’ve specialized in manufacturing high-quality precision parts that meet the strictest requirements. Our family-owned machine shop in Kaukauna, Wisconsin, combines decades of machining experience with modern CNC technology to deliver components that perform consistently and reliably.

Whether you need replacement parts for legacy equipment, prototypes for new product development, or high-volume production runs, we deliver precision parts built to exact specifications. Every part is produced with attention to detail, from material selection to final inspection, ensuring performance you can count on.

Why Precision Parts Matter

In industries such as aerospace, automotive, oil and gas, manufacturing and food industry there is no margin for error. Parts must meet exact tolerances to fit and function properly. Precision parts prevent failures, reduce downtime, and improve product performance.

When tolerances are off, the result can be costly repairs, safety risks, or complete system failures. That’s why partnering with an experienced machine shop like 4M Machine is critical. We have the equipment, processes, and expertise to ensure every part we produce is accurate, consistent, and dependable.

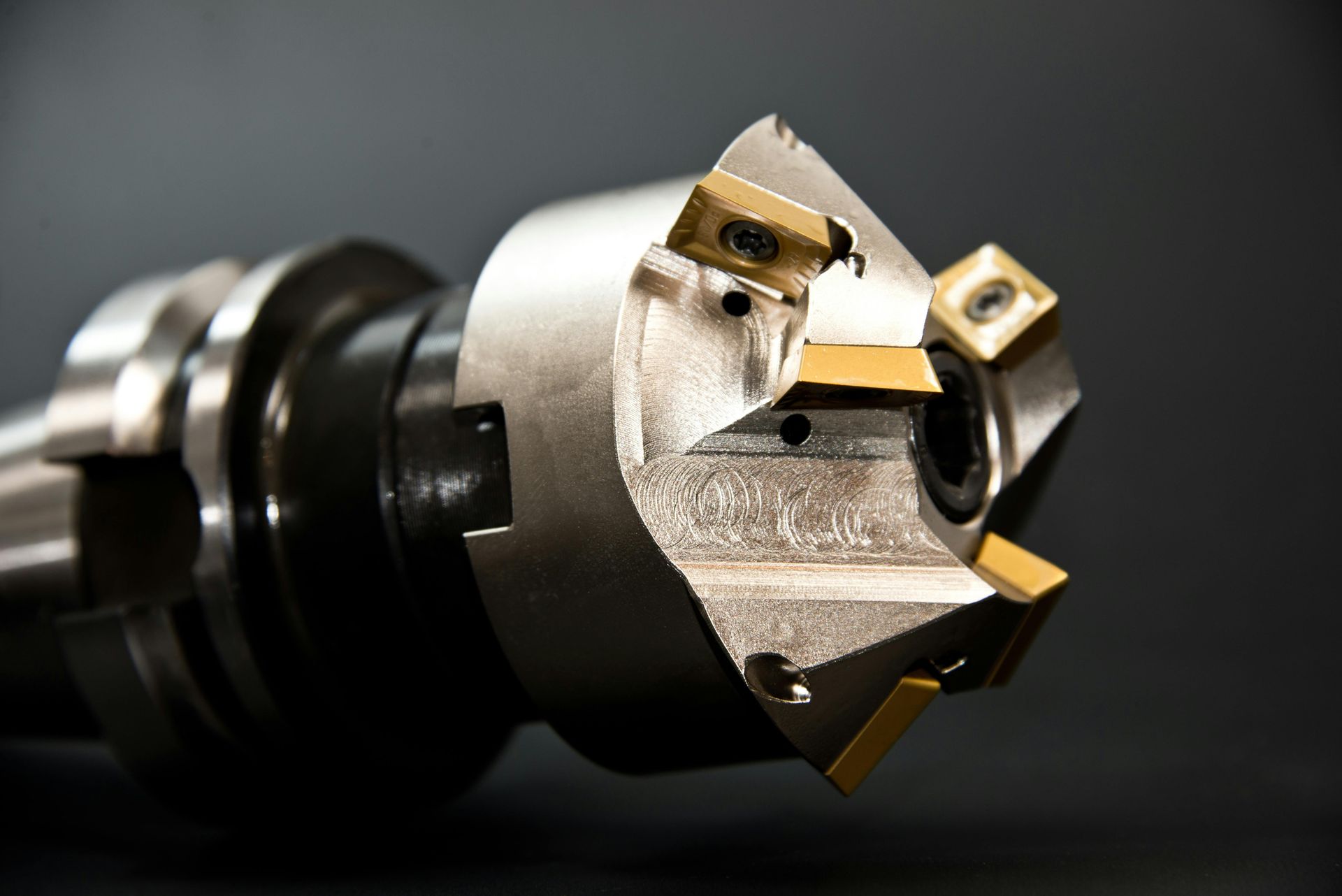

Precision parts

Our Precision Machining Capabilities

Our shop is equipped to handle projects of all sizes and levels of complexity. Our precision machining capabilities include:

Turning

Producing accurate cylindrical parts with smooth finishes.

Milling (Horizontal & Vertical)

Creating slots, pockets, holes, and complex shapes with precision.

Grinding (OD, Surface, Blanchard)

Achieving ultra-tight tolerances and fine finishes.

Welding (MIG and TIG)

Strong, precise welds for steel, stainless steel, and aluminum.

Reverse Engineering

Reproducing parts without drawings or replacing obsolete components.

Straightening

Ensuring proper surface preparation and part alignment.

Keyway Cutting

Accurate keyways for secure shaft and gear assemblies.

Refurbishment

Restoring worn or damaged parts to like-new condition.

This complete range of services allows us to produce precision parts from concept through completion—all under one roof.

Materials We Machine

We understand that different applications require different materials, each with its own machining challenges. Our machinists are skilled at working with:

- Aluminum

- Mild steel

- High-carbon steels

- Stainless steel

- Brass

- Bronze

- Nylon

- Plastics of all types

By applying the correct speeds, feeds, and tooling for each material, we ensure that your precision parts meet the strength, durability, and finish requirements of your application.

Benefits of Choosing 4M Machine for Precision Parts

When you need precision parts, accuracy is only part of the equation. 4M Machine goes beyond machining by offering:

01

Tight Tolerances: Consistency across single parts and large production runs.

02

Versatility: From parts up to 200 inches long to features as small as half an inch.

03

End-to-End Service: Reverse engineering, machining, welding, grinding, and finishing handled in one shop.

04

Experienced Team: Decades of knowledge in machining complex geometries and demanding materials.

05

Reliability: Clear communication and on-time delivery to keep your operations running smoothly.

06

Nationwide Service: Based in Kaukauna, WI, but trusted by customers across the U.S.

Industries That Rely on Our Precision Parts

Our precision parts support critical applications in industries such as:

01

Aerospace: Components that meet demanding performance and safety requirements.

02

Automotive: Prototypes, custom parts, and production runs for cars, trucks, and heavy equipment.

03

Oil & Gas: Durable parts designed for harsh environments and heavy-duty use.

04

Industrial Manufacturing: Replacement components, custom tooling, and fabricated parts for production lines.

05

Food Industry – Sanitary equipment fabrication, custom food processing parts, and maintenance solutions.

FAQs

How precise are the parts you can machine?

We specialize in tight-tolerance machining, achieving exact specifications to ensure proper fit and function.

Can you produce both small and large precision parts?

Yes. We machine parts up to 200 inches on our boring bar and down to one-half inch features on our vertical machining center.

What materials can be used for precision parts?

We machine aluminum, mild steel, high-carbon steels, stainless steel, brass, bronze, nylon, and most plastics.

Can you produce prototypes as well as production parts?

Absolutely. We offer precision prototypes to test designs and full production machining for consistent batches.

Do you provide reverse engineering for precision parts?

Yes. If drawings are missing or parts are obsolete, we can measure and recreate the part with precision.

Contact 4M Machine for Precision Parts

If your business requires precision parts that meet exact specifications, trust 4M Machine LLC to deliver. Call us at (920) 850-8121, email meyerhoferds@sbcglobal.net & 4mmachinellc@gmail.com, or visit us at W5021 Amy Ave, Kaukauna, WI 54130. We’re open Monday–Friday, 7:00 AM to 5:00 PM.

From reverse-engineered replacements to production-ready components, we deliver parts that perform.