Production Machining Services in Kaukauna, WI

Introduction to Production Machining

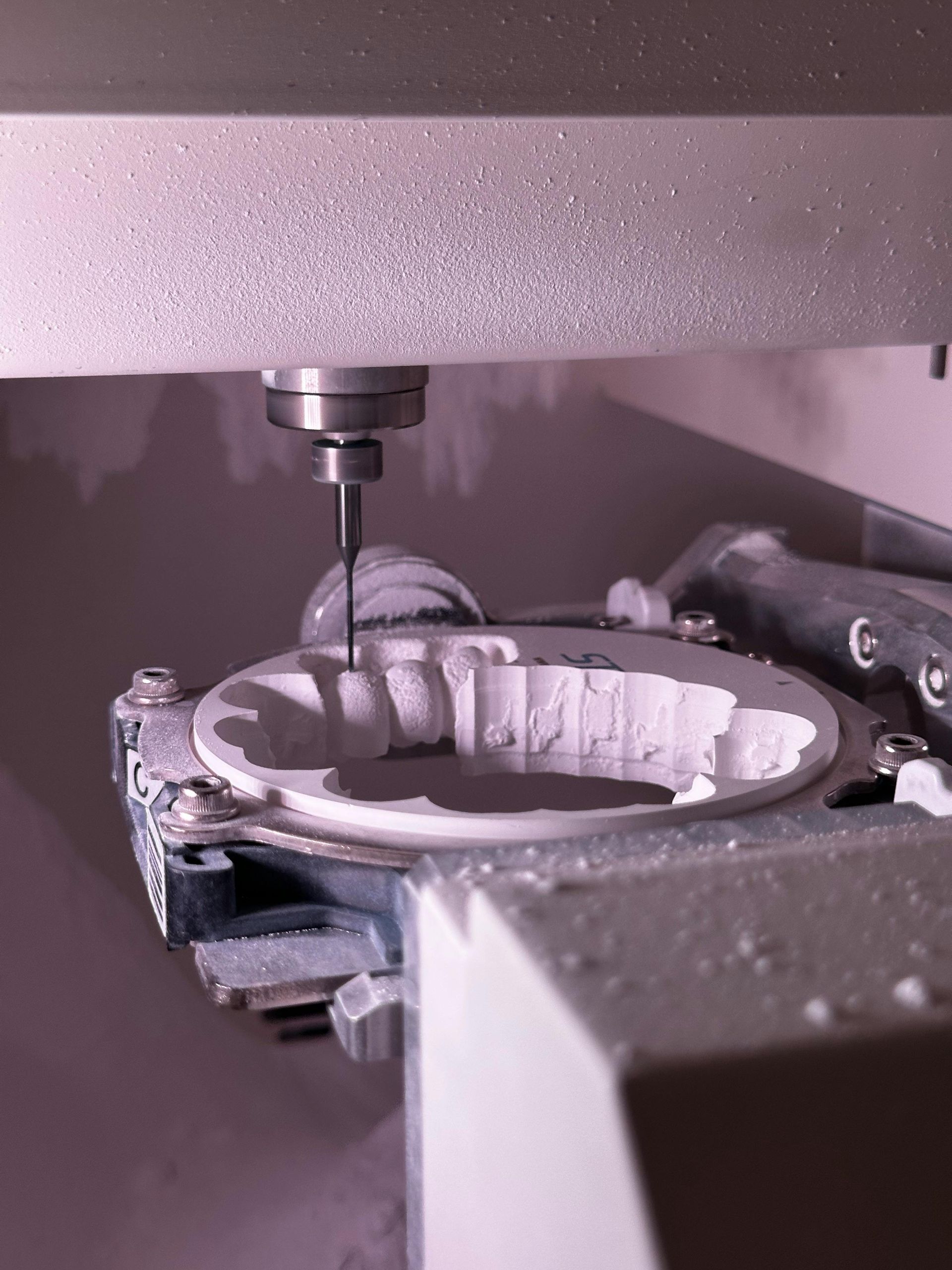

At 4M Machine LLC, we specialize in delivering production machining services that provide manufacturers with consistent, reliable parts. Based in Kaukauna, Wisconsin, our family-owned machine shop combines decades of machining expertise with advanced CNC technology to produce high-quality parts on time, every time.

From small-batch production to large-scale runs, we maintain tight tolerances and repeatability across every component. Whether you’re scaling up from a prototype or need an ongoing supply of critical parts, our team ensures each piece meets your exact specifications.

Why Production Machining Matters

In manufacturing, consistency is everything. A single out-of-spec part can cause failures, downtime, and lost revenue. Production machining is about more than just speed—it’s about delivering the same precision and quality across hundreds or thousands of parts.

Choosing a machining partner with proven experience in production means you can count on reliable parts, predictable schedules, and reduced costs over time. At 4M Machine, we’ve built our reputation on exactly that—repeatable excellence with every order.

Production Machining

Our Production Machining Capabilities

Our shop is fully equipped to handle production machining jobs of all sizes. Capabilities include:

CNC Turning and Milling (Horizontal & Vertical)

Producing complex geometries, slots, holes, and precision surfaces.

Grinding (OD, Surface, Blanchard)

Achieving smooth finishes and tight tolerances for production parts.

Welding (MIG and TIG)

Reliable, durable welds for steel, stainless, and aluminum components.

Straightening

Preparing and refining parts for durability and performance.

Keyway Cutting

Consistent, accurate keyways for production assemblies.

Reverse Engineering for Production

Converting a one-off part into a production-ready design.

Refurbishment

Extending part life and reconditioning production components.

We handle projects from parts measuring up to 200 inches in length down to intricate features just half an inch in size. This flexibility allows us to serve industries with a wide range of needs, from aerospace and automotive to oil and gas and heavy manufacturing.

From Prototype to Production

One of our greatest strengths is helping customers transition smoothly from prototype to production. When you test a prototype with 4M Machine, we capture every detail—drawings, CNC programs, setups, and tooling. This means when you’re ready for production, we can replicate the prototype precisely at scale.

Our ability to carry projects from the design stage through production eliminates costly rework and ensures your production parts are identical to your approved prototype. That continuity gives you confidence and saves valuable time.

Materials We Machine in Production

We work with a wide range of materials to deliver production machining solutions that meet diverse applications. Common materials include:

- Aluminum

- Mild steel

- High-carbon steels

- Stainless steel

- Brass

- Bronze

- Nylon

- Plastics of all types

By applying the right machining strategies for each material, we ensure durability, strength, and accuracy in every production part.

Benefits of Choosing 4M Machine for Production Machining

When you partner with 4M Machine for production machining, you gain:

01

Repeatable Accuracy: Every part meets your exact specifications, no matter the quantity.

02

Flexible Volumes: From short runs to large-scale production, we adapt to your needs.

03

In-House Solutions: Machining, welding, grinding, finishing, and refurbishment done under one roof.

04

Industry Experience: Serving aerospace, automotive, oil and gas, and industrial manufacturing.

05

On-Time Delivery: Clear scheduling and communication to keep your project moving.

06

Trusted Quality: Decades of experience backed by a family-owned commitment to doing things right.

Industries That Rely on Our Production Machining

Our production machining services support critical industries nationwide, including:

01

Aerospace: Precision parts for high-performance systems.

02

Automotive: Reliable components for vehicles and heavy equipment.

03

Oil & Gas: Durable parts designed for extreme conditions.

04

Industrial Manufacturing: Consistent production runs for replacement parts and custom components.

05

Food Industry – Sanitary equipment fabrication, custom food processing parts, and maintenance solutions

FAQs

What production volumes do you handle?

We handle everything from small-batch runs to large-scale production orders.

Can you transition a prototype into production?

Yes. We specialize in taking prototypes and scaling them into repeatable production runs.

What tolerances can you achieve in production machining?

We hold tight tolerances across all parts, ensuring accuracy and consistency in every batch.

Do you offer welding and finishing in production jobs?

Yes. We provide MIG and TIG welding, grinding and other finishing services in-house.

Do you serve customers outside Wisconsin?

Absolutely. While we are based in Kaukauna, WI, we serve customers across the United States.

Contact 4M Machine for Production Machining

When you need reliable, repeatable production machining, trust 4M Machine LLC to deliver. Call us at

(920) 850-8121, email

meyerhoferds@sbcglobal.net &

4mmachinellc@gmail.com, or visit us at

W5021 Amy Ave, Kaukauna, WI 54130. Our hours are Monday–Friday, 7:00 AM to 5:00 PM.

From prototypes to high-volume runs, we provide precision machining that keeps your operations moving and your parts performing.