Prototype Machining Services in Kaukauna, WI

Introduction to Prototyping at 4M Machine

Every great product begins with an idea, but transforming that idea into a working part requires precision, expertise, and the right machining partner. At 4M Machine LLC, we specialize in machining prototypes that help manufacturers bring concepts to life. From a simple design sketch to a complex engineered drawing, our experienced machinists create accurate, functional prototypes that are ready for real-world testing.

For more than 20 years, our family-owned shop in Kaukauna, Wisconsin, has provided prototype machining services to businesses across aerospace, automotive, oil and gas, and industrial manufacturing. With deep knowledge of reverse engineering, CNC machining, and material selection, we offer end-to-end support for customers who need one-off samples, iterative design changes, or small production test runs.

Prototyping is often the most critical stage of product development. It allows you to test ideas, refine designs, and make improvements before committing to high-volume production. That’s why at 4M Machine, we treat every prototype with the same attention to detail as a finished production part.

Why Prototyping Matters

Prototypes serve as the foundation for decision-making in product design and manufacturing. They allow engineers, designers, and manufacturers to:

Validate fit and function

Confirm that parts meet design intent and assemble correctly.

Test material performance

Evaluate how different materials withstand stress, wear, and environmental conditions.

Identify design improvements

Detect flaws or inefficiencies before investing in tooling or production.

Shorten time to market

Use working models to accelerate approvals, attract investors, or secure contracts.

Ensure production readiness

Transition seamlessly from prototype to scaled manufacturing.

Without a dependable prototype, businesses risk launching flawed products, wasting resources, or facing costly redesigns. Our prototype machining services minimize these risks by delivering parts that closely represent the final production version.

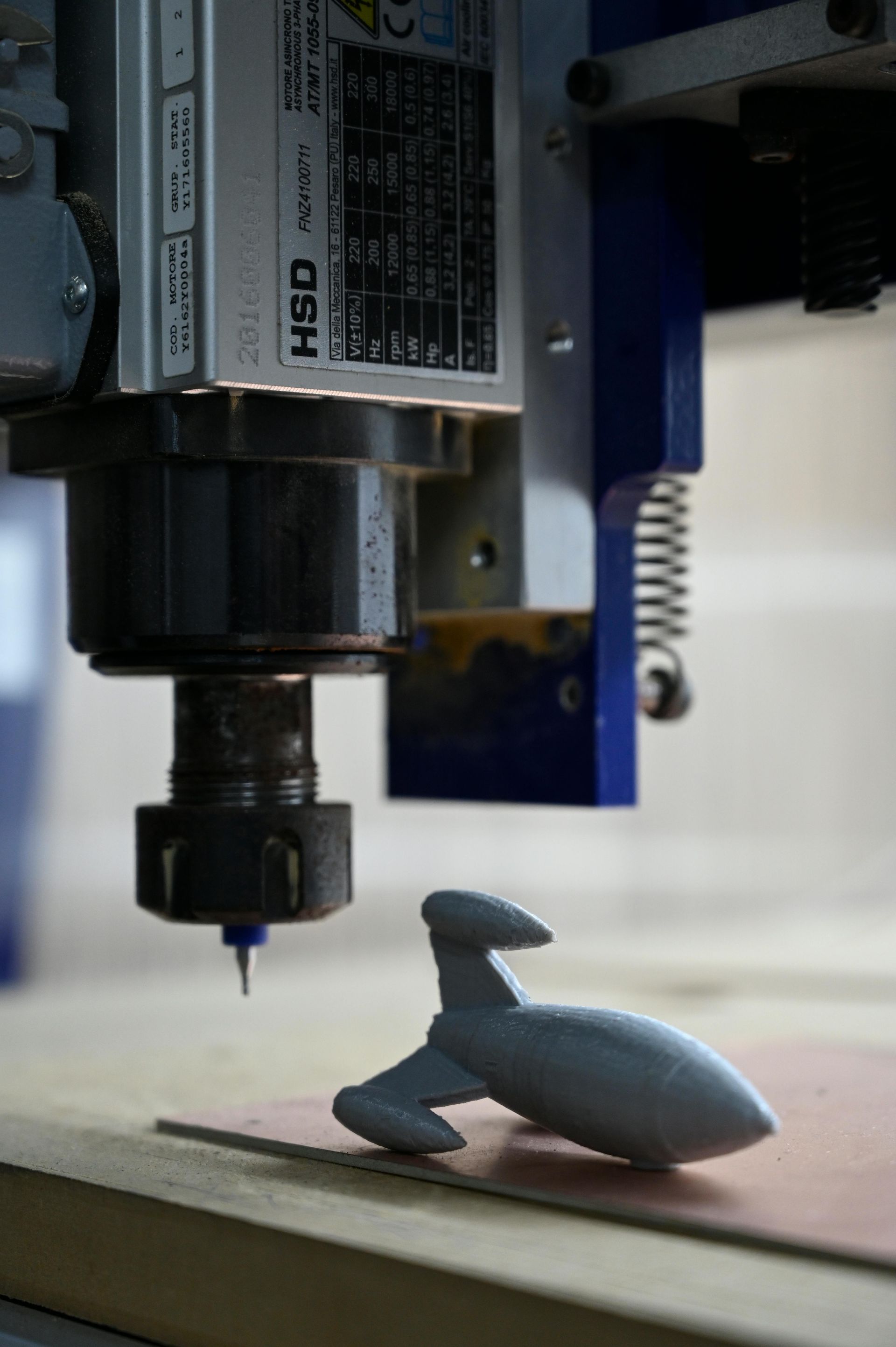

Prototypes

Our Prototype Machining Capabilities

We provide a complete suite of machining services to support prototypes of all shapes and sizes:

Reverse Engineering

Ideal for when drawings are unavailable, outdated, or incomplete.

Turning and Milling (Horizontal & Vertical)

Precision CNC machining for complex features and geometries.

Grinding (OD, Surface, Blanchard)

High-precision finishing for critical tolerances.

MIG and TIG Welding

For steel, stainless, and aluminum assemblies.

Straightening

Preparing surfaces and restoring alignment for accurate testing.

Keyway Cutting

Creating secure connections for shafts, gears, and mechanical assemblies.

Refurbishment

Extending prototype life by restoring worn or damaged parts.

Our equipment can handle oversized prototypes up to 200 inches long and intricate details as small as half an inch, giving you flexibility for everything from heavy-duty industrial parts to precision miniature components.

Materials We Use for Prototypes

Material selection plays a major role in prototype development. We machine prototypes using the same materials intended for production, ensuring that testing accurately reflects final performance. Common options include:

- Aluminum

- Mild steel

- High-carbon steels

- Stainless steel

- Brass

- Bronze

- Nylon

- Plastics of all kinds

Our machinists understand the strengths and challenges of each material, adjusting feeds, speeds, and tooling to achieve optimal results.

Benefits of Partnering with 4M Machine for Prototypes

Working with 4M Machine gives you more than just a prototype—it gives you confidence in your product development process. Advantages include:

01

Accuracy You Can Trust: We build prototypes with tight tolerances and repeatable results.

02

Flexibility for Iteration: We can modify prototypes quickly as designs evolve.

03

Production-Ready Consistency: Our processes allow for easy scaling from prototype to production.

04

Industry Expertise: Decades of experience serving aerospace, automotive, oil and gas, and manufacturing clients.

05

In-House Solutions: Prototyping, machining, welding, grinding, and finishing handled under one roof.

06

Personalized Service: Clear communication and accountability from a family-owned business.

From Prototype to Production

At 4M Machine, we understand that a prototype is not the end goal—it’s the starting point. Once your prototype is approved, we seamlessly transition into production machining. Using the same setups, tooling, and documentation, we ensure that production runs match your prototype precisely, eliminating inconsistencies and reducing lead times.

This continuity means that when you partner with us, you don’t have to start over with a new vendor once your design is finalized. We’re with you every step of the way, from concept to completion.

FAQs

Can you make a prototype without a detailed drawing?

Yes. Our reverse engineering expertise allows us to measure existing parts and create prototypes from scratch.

Do you machine prototypes in production-grade materials?

Absolutely. We use the same materials intended for production to ensure accurate testing and performance validation.

How quickly can you deliver a prototype?

Lead times vary, but our in-house equipment and efficient processes allow us to provide fast turnaround without compromising quality.

Can you modify a prototype if my design changes?

Yes. We can adjust features, dimensions, or materials to refine your design as needed.

Do you also provide production machining once the prototype is approved?

Yes. We offer full production machining services, ensuring a seamless transition from prototype to scaled manufacturing.

Contact 4M Machine for Prototyping Services

If you’re ready to take your design from concept to reality, trust 4M Machine LLC for reliable prototype machining. Call us at (920) 850-8121, email meyerhoferds@sbcglobal.net & 4mmachinellc@gmail.com, or visit us at W5021 Amy Ave, Kaukauna, WI 54130. We’re open Monday–Friday, 7:00 AM to 5:00 PM.

From reverse-engineered samples to production-ready prototypes, we provide the precision and service you need to move your project forward with confidence.